Engineering Precision, Delivering Excellence Globally

Reliable and leak-proof compression tube fittings designed for seamless and secure connections in diverse applications.

Flange fittings by Kostevo deliver precision, durability, and reliability for seamless industrial and pipeline connections.

Cutting-edge gear engineered for performance, innovation, and reliability—elevate every experience with Kostevo.

Precision-engineered fasteners by Kostevo ensure strength, durability, and reliability for every application.

Pipe fitting solutions from Kostevo ensure precision, durability, and seamless integration for all your piping needs.

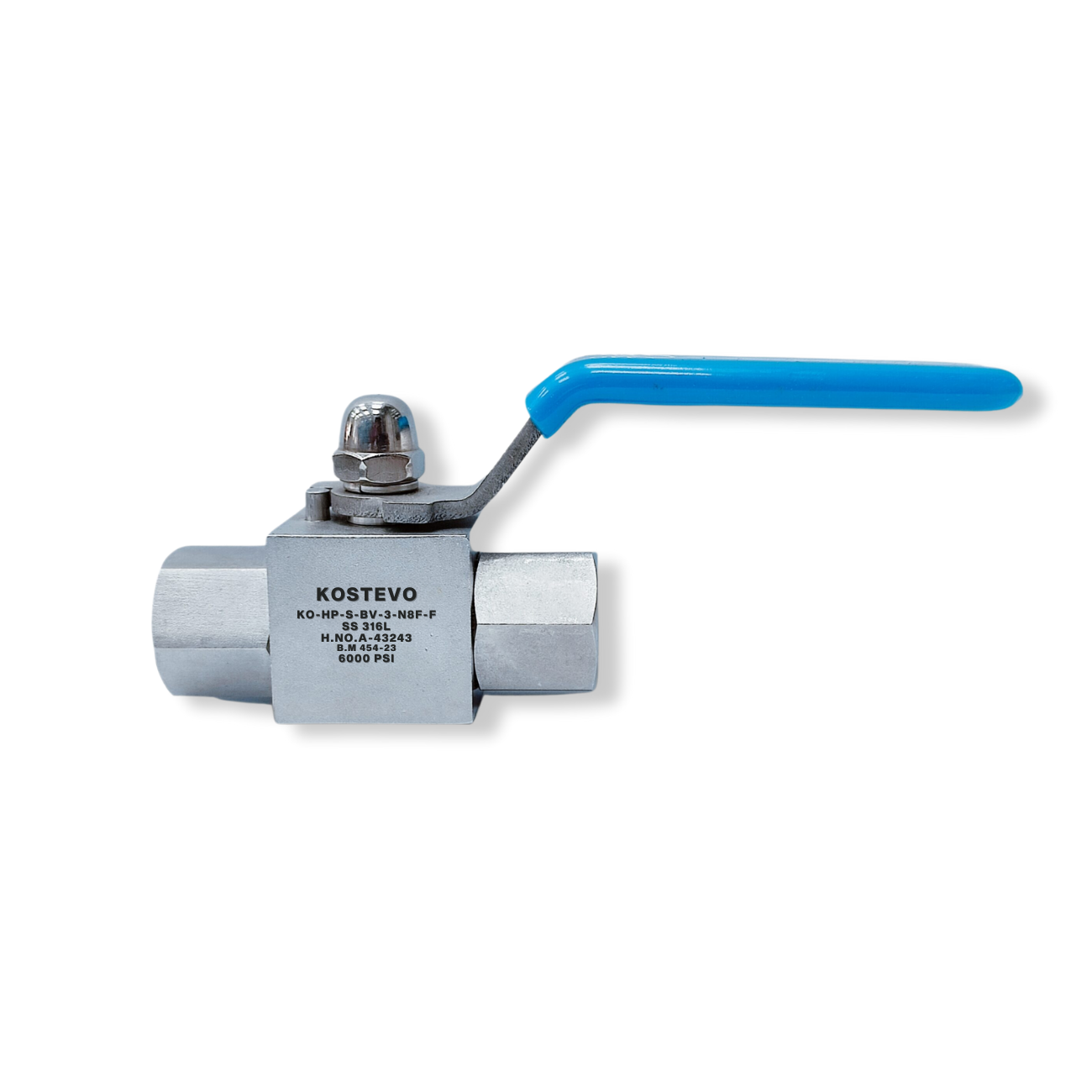

Precision-engineered industrial valve fittings designed for reliability, efficiency, and durability in diverse applications.

What we beleive

A leading industry innovator with a rich history of excellence.

Kostevo has been well-versed in precision machining for the past 15 years. In the designing like the Compression Tubes, Fasteners, Flanges, Gears, Industrial Valves, Pipe Fittings and any kind of precision work. We are capable of manufacturing non-standard parts as per customer requirements for generators, turbines, motors, pumps, compressors and gearboxes.

Catering to a diverse range of industries with precision-engineered products and solutions that meet sector-specific standards and challenges. From Oil & Gas to Pharmaceuticals, and from Automotive to Power Generation, our expertise ensures that each industry receives tailored support to drive efficiency, innovation, and growth. Discover how our products and services adapt to unique demands, powering advancements and contributing to sustainable development across multiple fields.

Kostevo delivers robust, high-performance components designed to withstand the challenging conditions of the oil and gas industry. From exploration to refining, our solutions support each stage of the process with precision-engineered parts that enhance operational efficiency, reliability, and safety. Our expertise enables oil and gas companies to tackle complex projects with confidence, ensuring consistent performance in critical applications and harsh environments.

Kostevo is dedicated to supporting the pharmaceutical industry with precision-engineered components and assemblies that meet the highest standards of safety, quality, and reliability. Our products play a crucial role in ensuring the safe, effective production and handling of medicines, from drug manufacturing to packaging and distribution. We provide specialized solutions designed to withstand rigorous processes, support stringent compliance requirements, and enhance efficiency in pharmaceutical operations.

Kostevo delivers high-performance components and solutions tailored to the demands of the power generation industry, including renewable energy, fossil fuels, and nuclear power. Our precision-engineered products are designed to enhance efficiency, reliability, and durability in power systems, helping to support uninterrupted energy production. From turbine components to critical fittings, we provide solutions that withstand extreme conditions and support sustainable power generation processes, ensuring consistent output and long operational lifespans.

Step inside the world of Kostevo, where cutting-edge technology meets unparalleled expertise in precision machining. Kostevo has been a leader in designing, including hydrodynamic bearings, valve-tube fittings and specialized seals and any kind of precision work.

Our clients, a diverse community of tastemakers, luxury enthusiasts, and global sophisticates, embody the essence of our brand. From those with discerning styles to timeless elegance enthusiasts, we are honored to serve a clientele that appreciates the artistry and sophistication embedded in every fragrance we offer.