BEARING WARRANTY SECOND TO NONE

We provide 8,000 working hours or 2 years warranty for all manufactured and repaired bearings.

QUALITY MATERIALS & QMS

All white metal lined components are manufactured or repaired using virgin white metal imported from Europe. Our quality standards are second to none. Please visit our facility to see for yourself.

ALWAYS AVAILABLE

With a technical team that is experienced and sound, and a team of sales engineers working around the clock based in Riyadh and Jubail, we are just a stone’s throw away and are always reachable for any urgent requests.

LOWER PRICE POINT

Quality VS price point offers great value

BEARINGS MANUFACTURE & REPAIR

There are three key requirements in manufacturing a reliable bearing system:

- Capability in metallurgical casting technology,

- Knowledge of tribology and metal systems, and

- The ability to control hydrodynamic oil films.

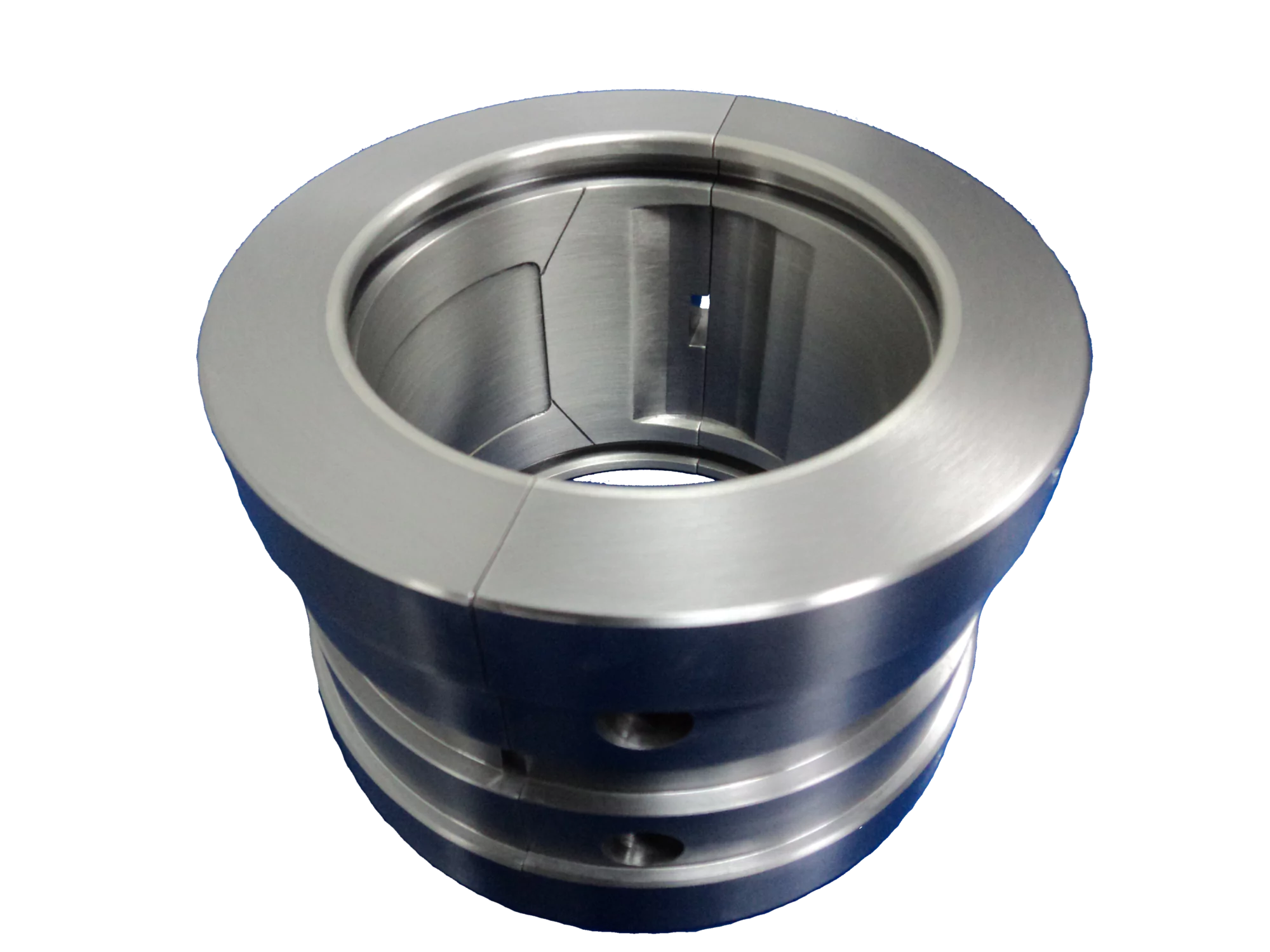

WHITE METAL PROCESSES

Centrifugal casting is recognized as the best technique to line bearings with white metal. This is aided by ensuring a thorough bonding process by fully inserting the bearing in pure tin before the casting process. Depending on the type, all bearings are manufactured and repaired using centrifugal casting with our very own spin casting machine.

CENTRIFUGAL CASTING

A process by which natures centrifugal force is used to apply babbitt to the bearing surface

STATIC CASTING

A process particularly useful when metaling thrust shoes and unusually shaped bearings.

GTA PROCESS

A welding method of applying babbitt to an existing babbitted surface.

ROTATING EQUIPMENTS MANUFACTURE & REPAIR

Kostevo provides services to both – End users and Original Rotating Equipment Manufacturers

CAPABILITIES

We can manufacture and repair a wide variety of components and parts for:

- Turbines,

- Gearboxes,

- Generators,

- Fans,

- Motors,

- Compressors,

- Pumps, and

- Diesel Engines.

COMPONENTS WE EXCEL AT

An example of the components we can deliver are:

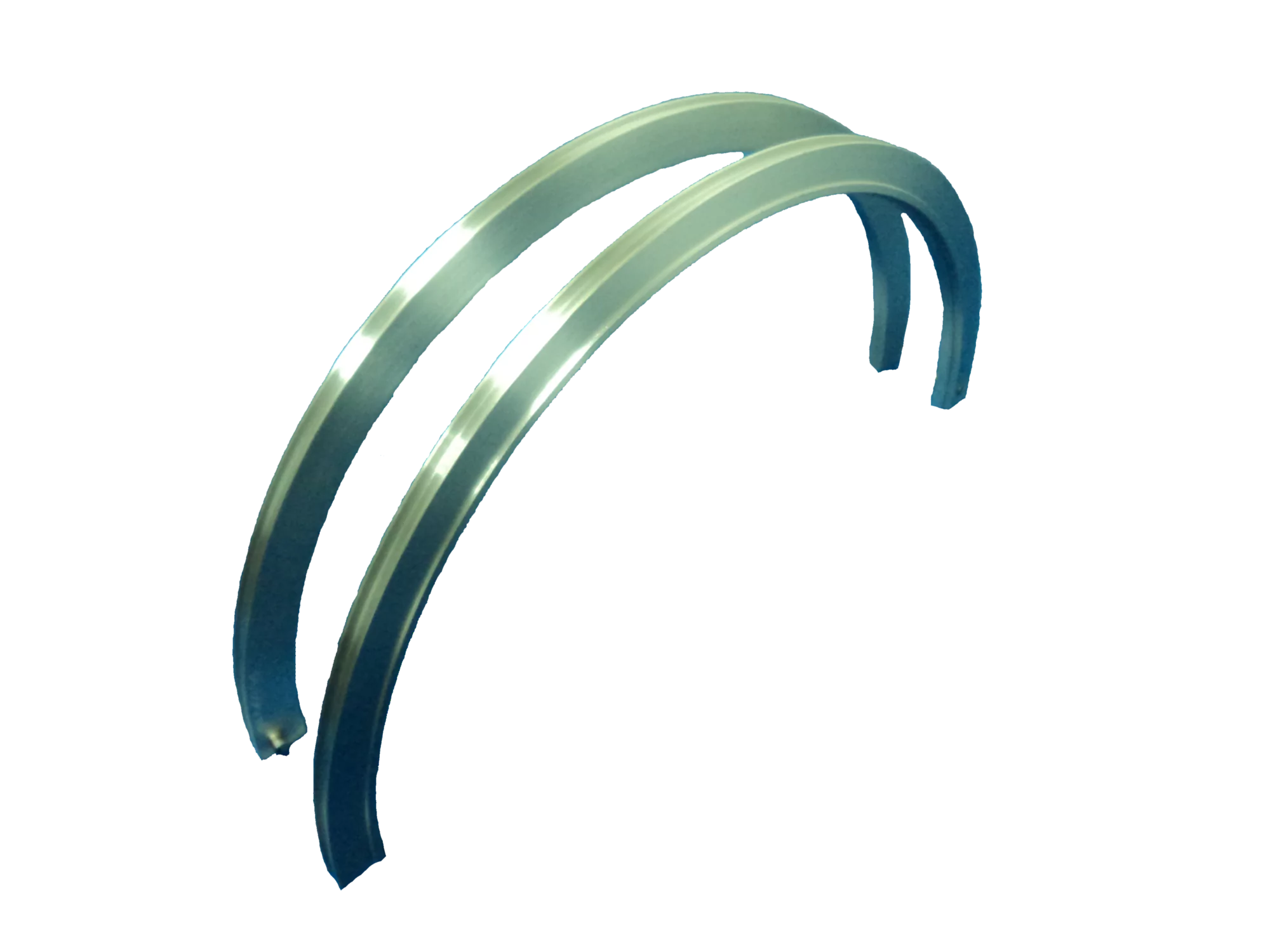

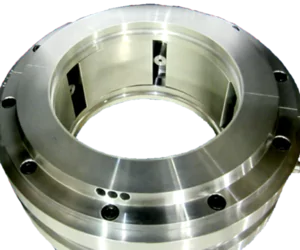

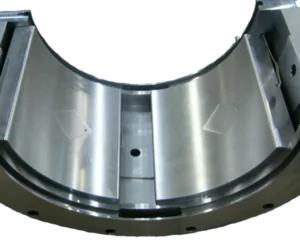

- Journal bearings (Sleeve),

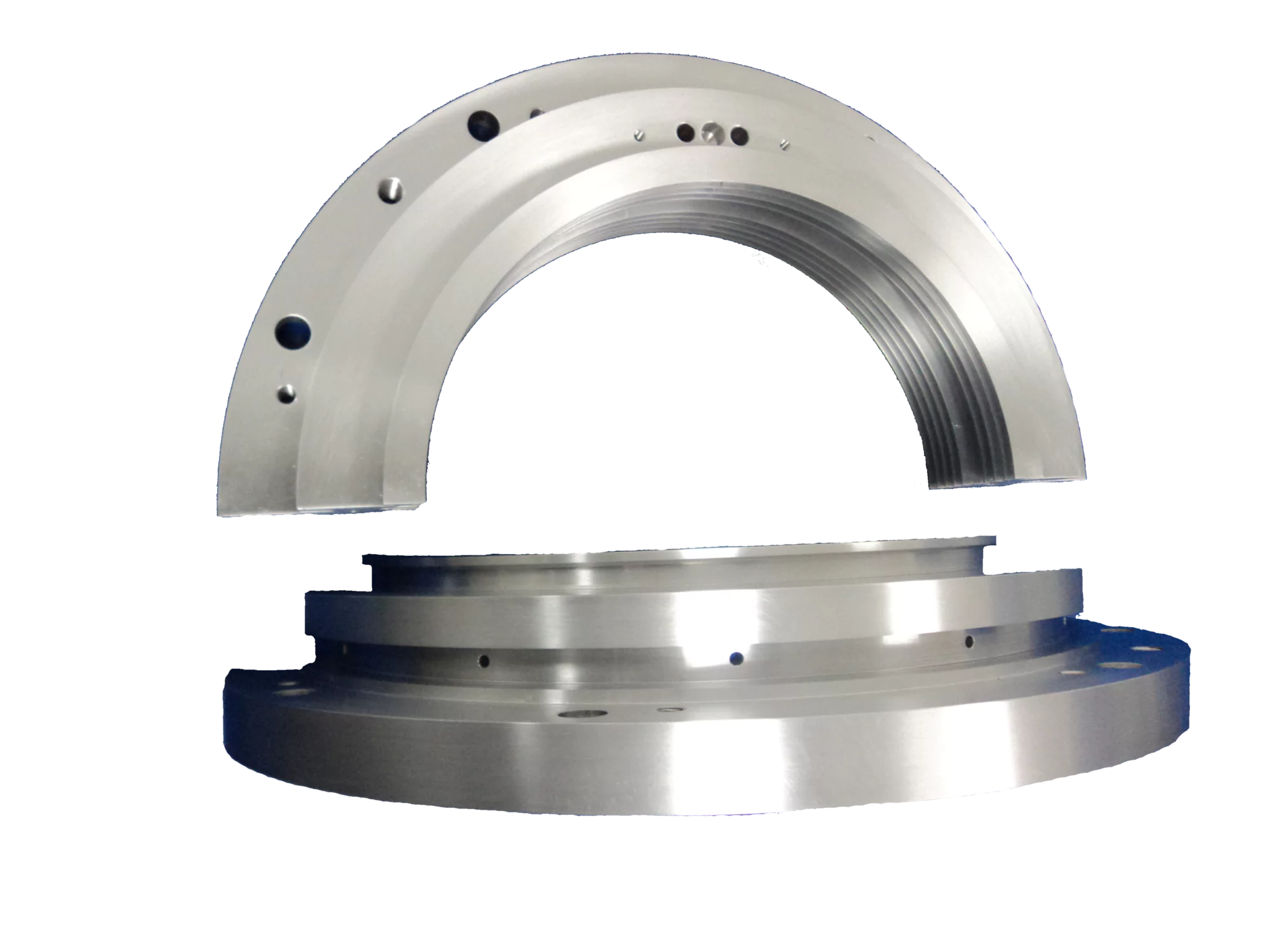

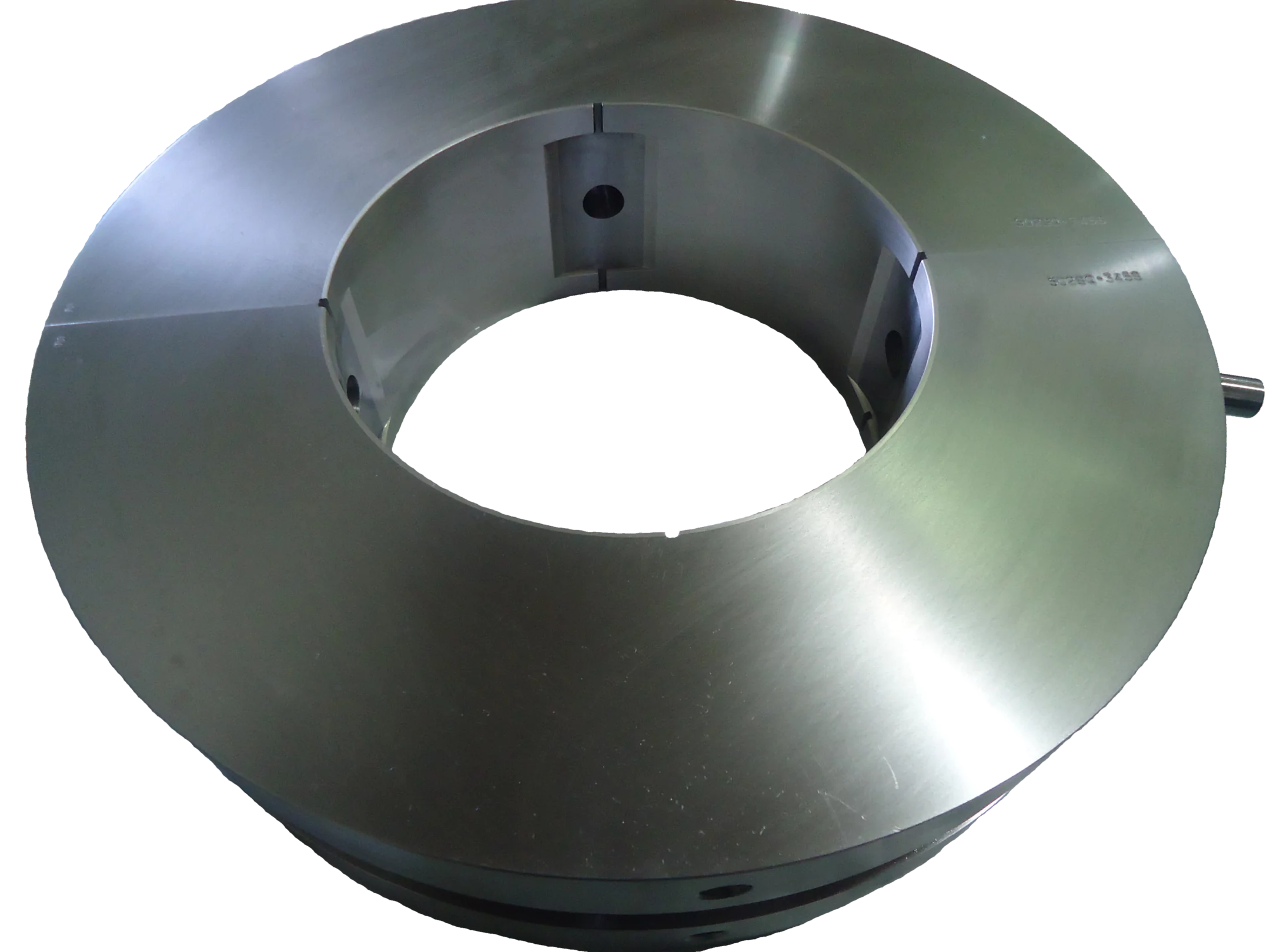

- Thrust bearings,

- Combined Journal & Thrust Bearings,

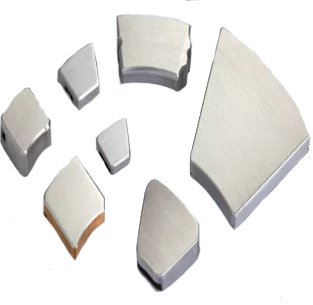

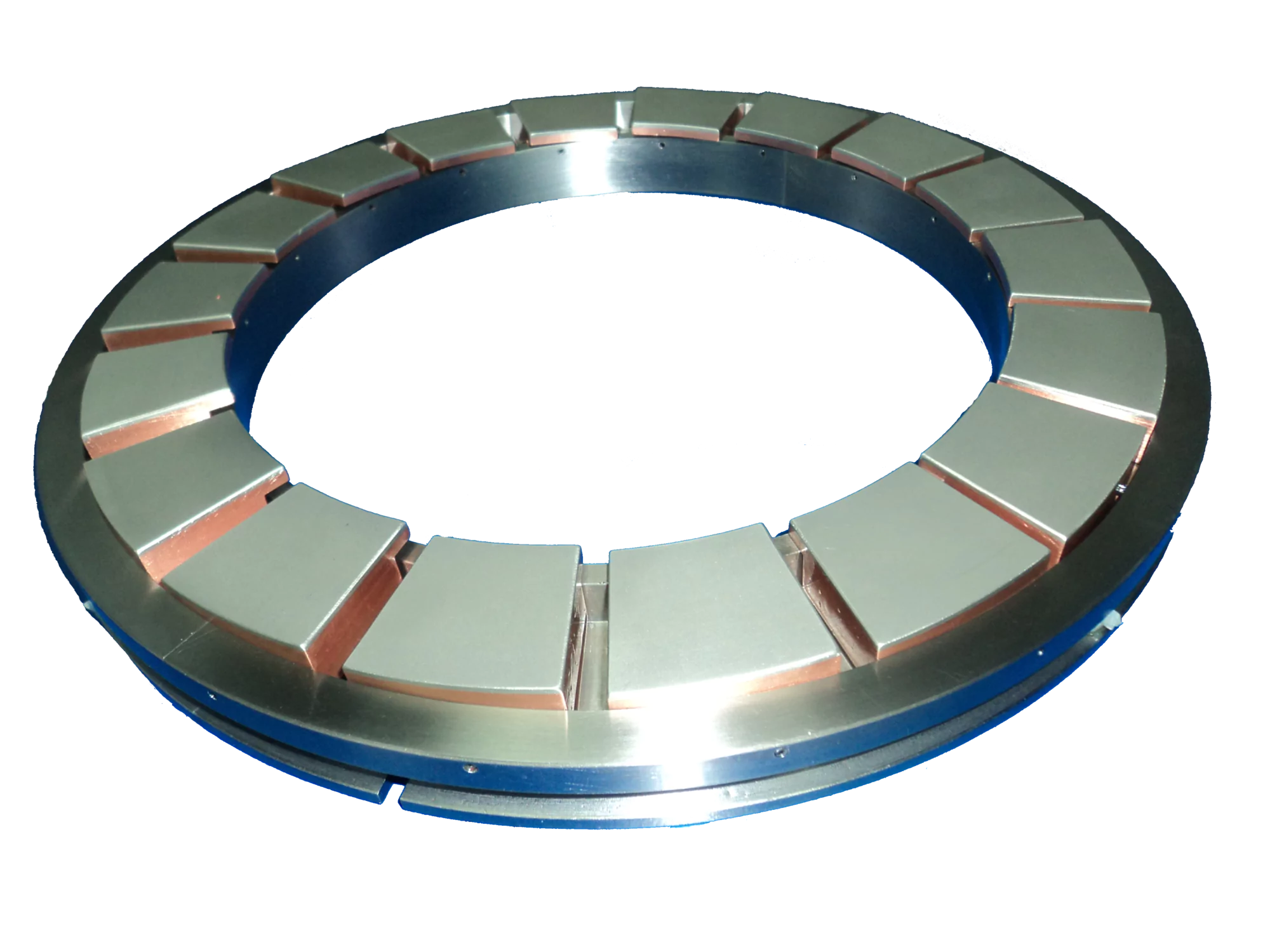

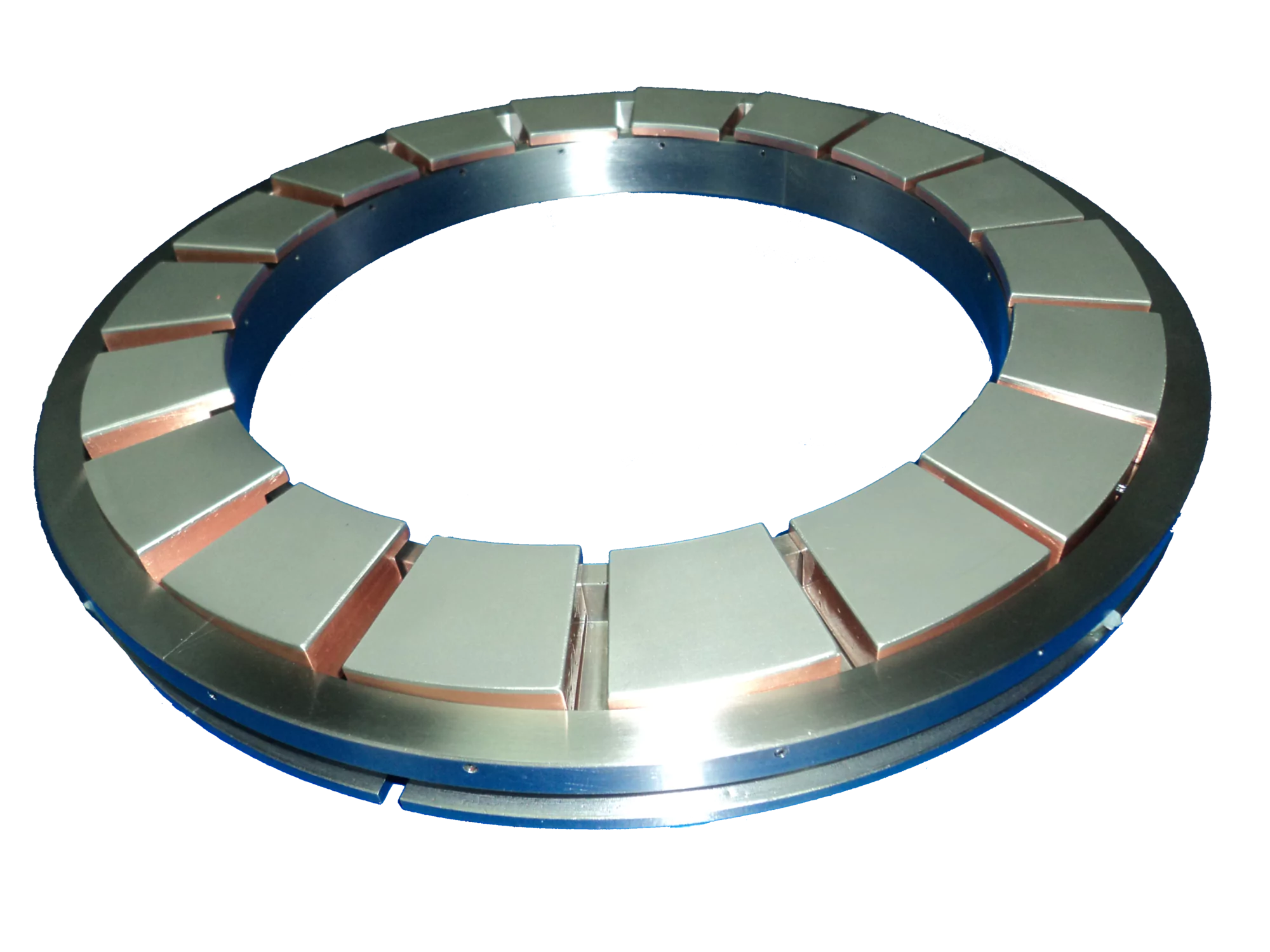

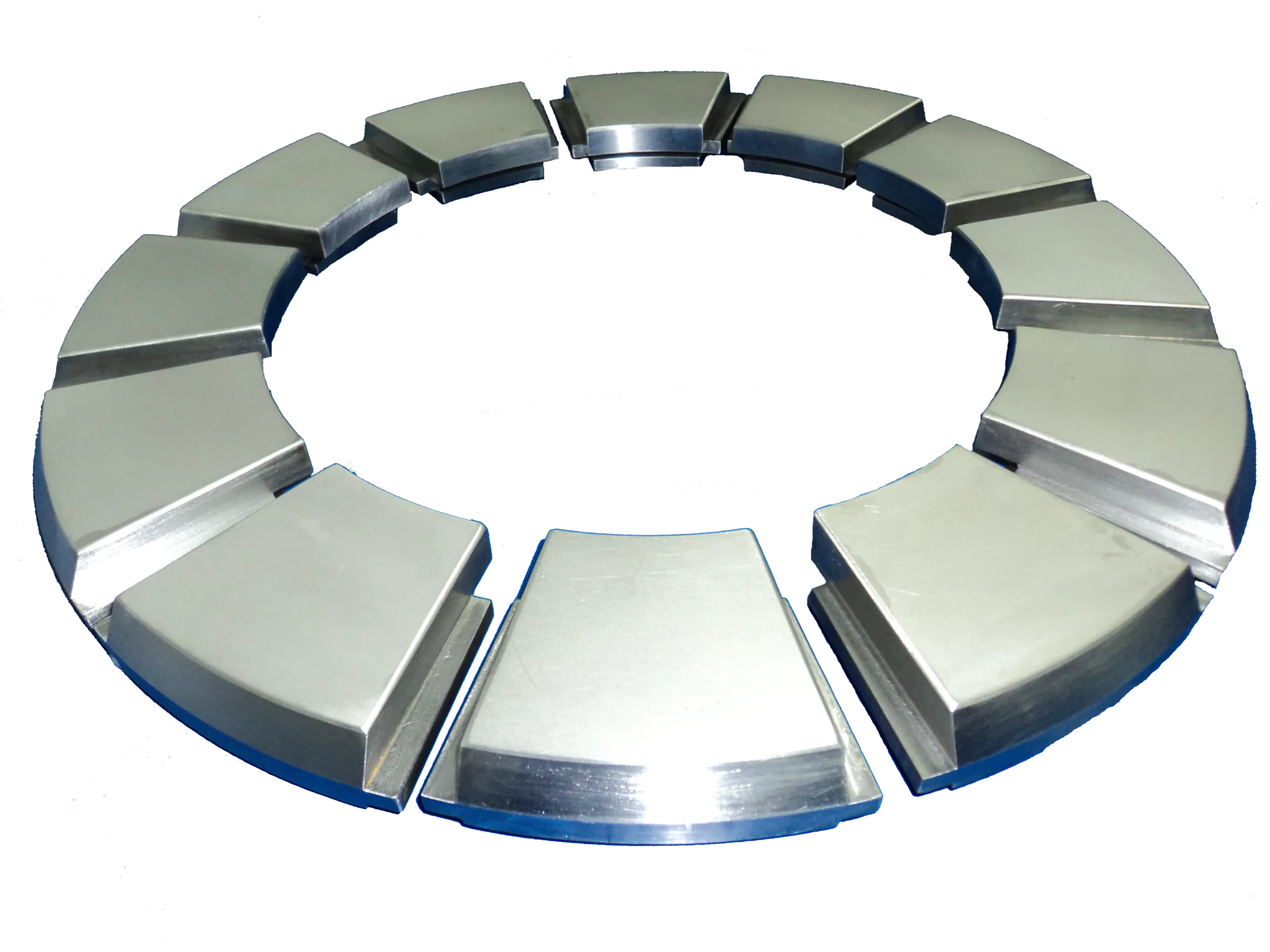

- Thrust Pads,

- Journal Pads,

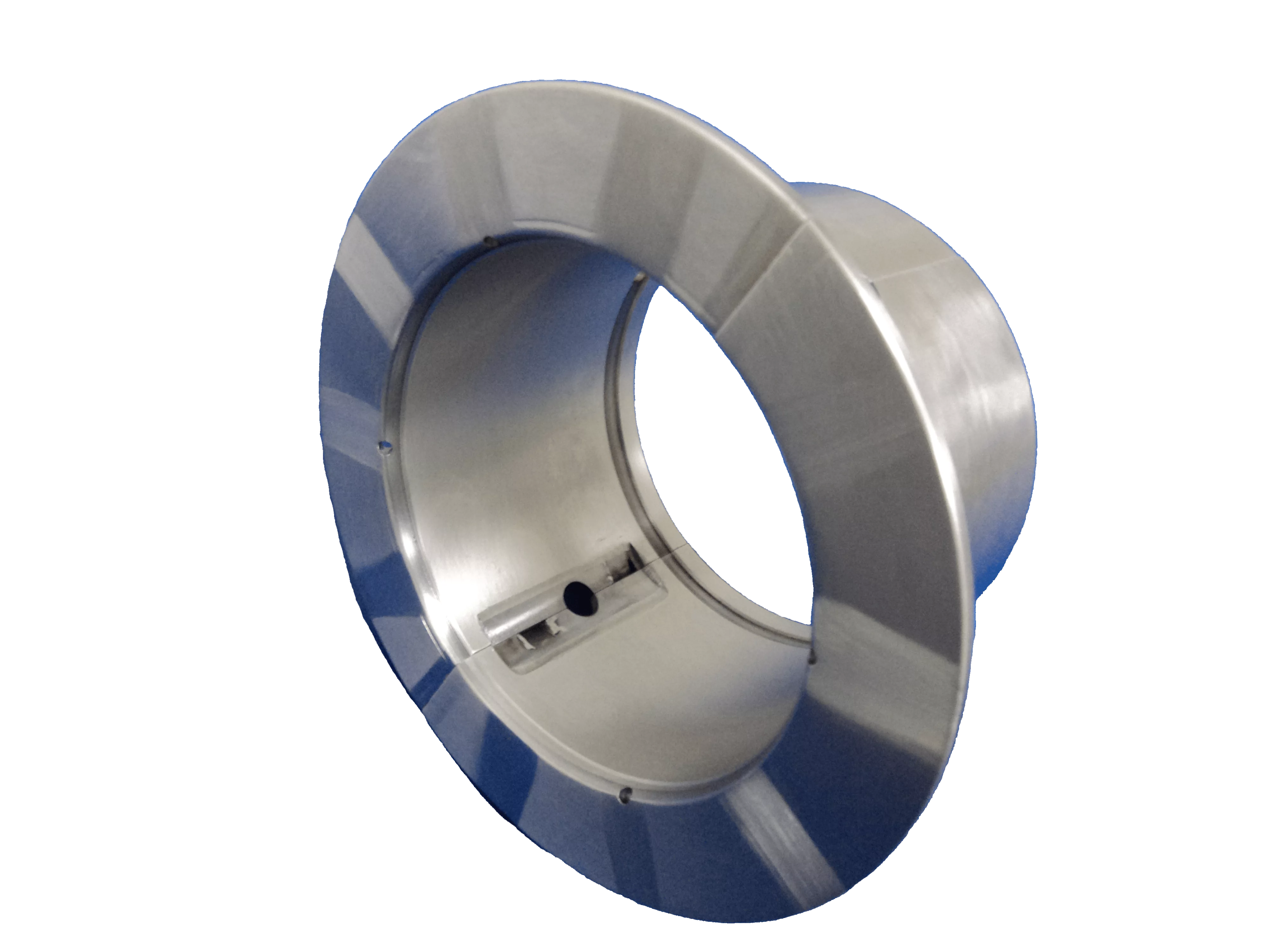

- Generator end Caps,

- Oil Deflectors,

- Crosshead Slides,

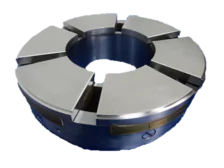

- Hydrogen Seals,,

- Seal Rings, and

- Oil Seals to Name a few.

MANUFACTURED COMPONENTS

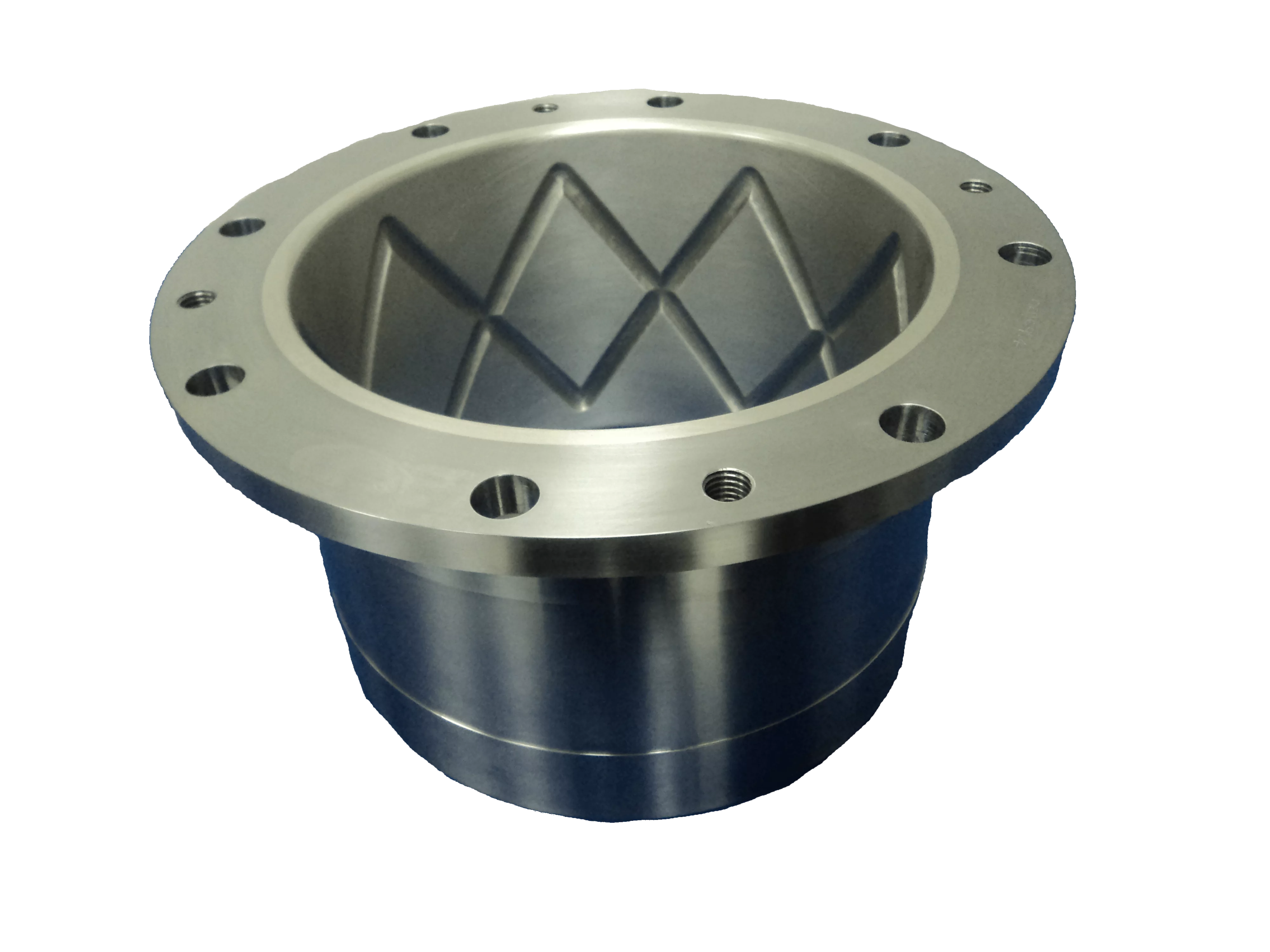

HS Seals for Gear Boxes

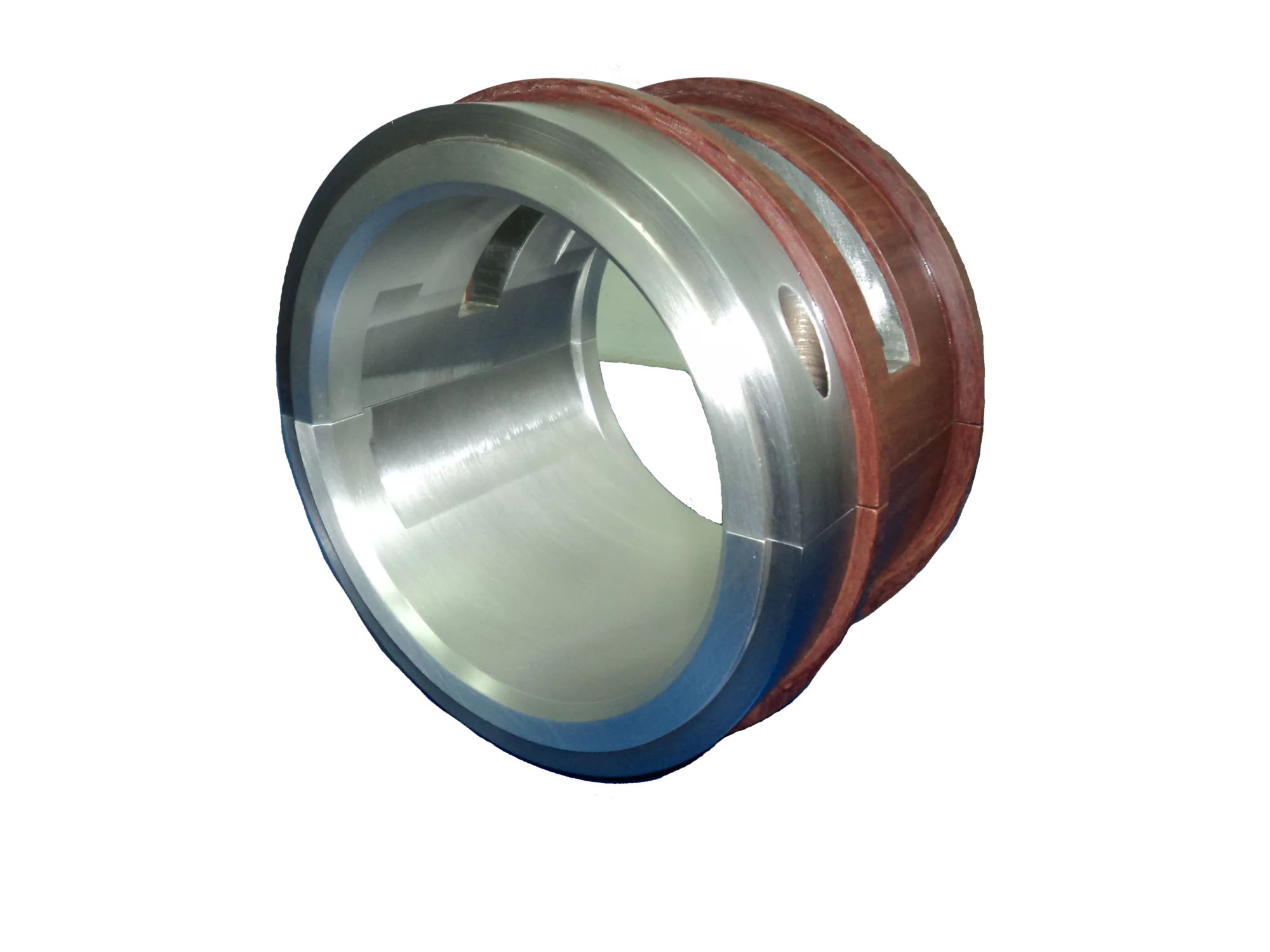

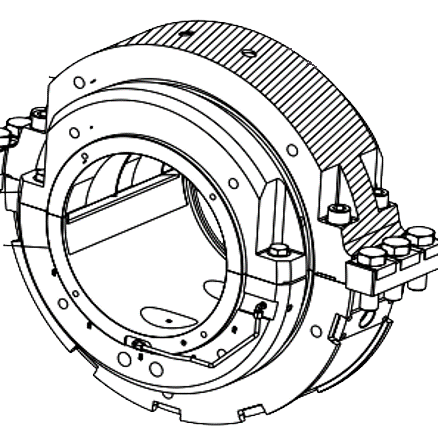

Pad Seated Bearings with End Seals

Motor Bearings

Floating Seals

Journal Pads for Vertical Bearings

Pressure Dam Bearings

Tilting Pad Journal Bearings

Thrust Bearing Assembly

Turbine Loaded Thrust Bearings

REPAIRED COMPONENTS

Lube Oil Pump Bearings

Unloaded Thrust Bearings for Turbines

Tilting Pad Journal Bearings

Insulated Motor Bearings

Gear Box Bearings – 4 Lobe

Vertical Bearing Thrust Pads

REVERSE ENGINEERING

For Manufacture & Repair

Kostevo is able to re-engineer replacements for small and large components. These parts can be manufactured or repaired as an exact duplicate or even modified for improved performance characteristics based on client requirements.

QUALITY CONTROL

Quality is never an accident; it is always the result of high intention, sincere effort, intelligent direction, and skillful execution; it represents the wise choice of many alternatives.” – William A.

Quality Assurance and Quality Control Procedures

ISO 9001:2015

Kostevo is able to re-engineer replacements for small and large components. These parts can be manufactured or repaired as an exact duplicate or even modified for improved performance characteristics based on client requirements.

- Incoming Job Inspection

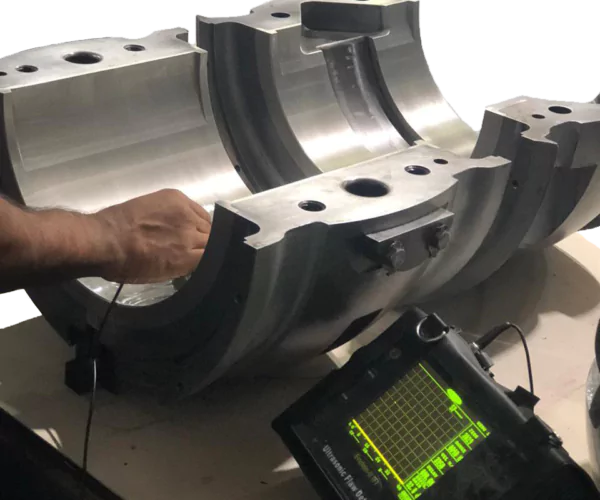

- Surface Finish Testing Ultrasonic Inspection

- Non-destructive testing (NDT)

- Final Progress/Dispatch Testing/Delivery

GOODS INWARD INSPECTION

On receiving the components, a comprehensive dimensional and visual check of their original state is made.

An initial inspection report will then be forwarded outlining these facts and whether a good repair is feasible.

COMPONENT INSPECTION

All manufactured or repaired components undergo visual, dimensional, ultrasonic and where requested dye penetrant inspections. Dimensions are checked to ensure that every critical one is within tolerance given by the drawings.